The Île-Bizard-Sainte-Geneviève Community Centre

Project Overview

This pilot project was chosen to address a widespread need: thousands of "Butler barn"-type prefab steel buildings such as this one house community centres and arenas across Quebec and Canada. Some also serve as emergency shelters, while many have significant deficiencies and need major upgrades.

Our team and collaborators aim to develop DER solutions tailored to the Ile Bizard Community Centre that can then be applied with minor adjustments to a large number of similar buildings, offering a scalable model and a broader regional impact.

Work completed and in progress

- Building capture to BIM (digital twin)

- Monitoring (measurement & verification)

- Energy modeling & Life cycle assessment (LCA)

- Structural analysis

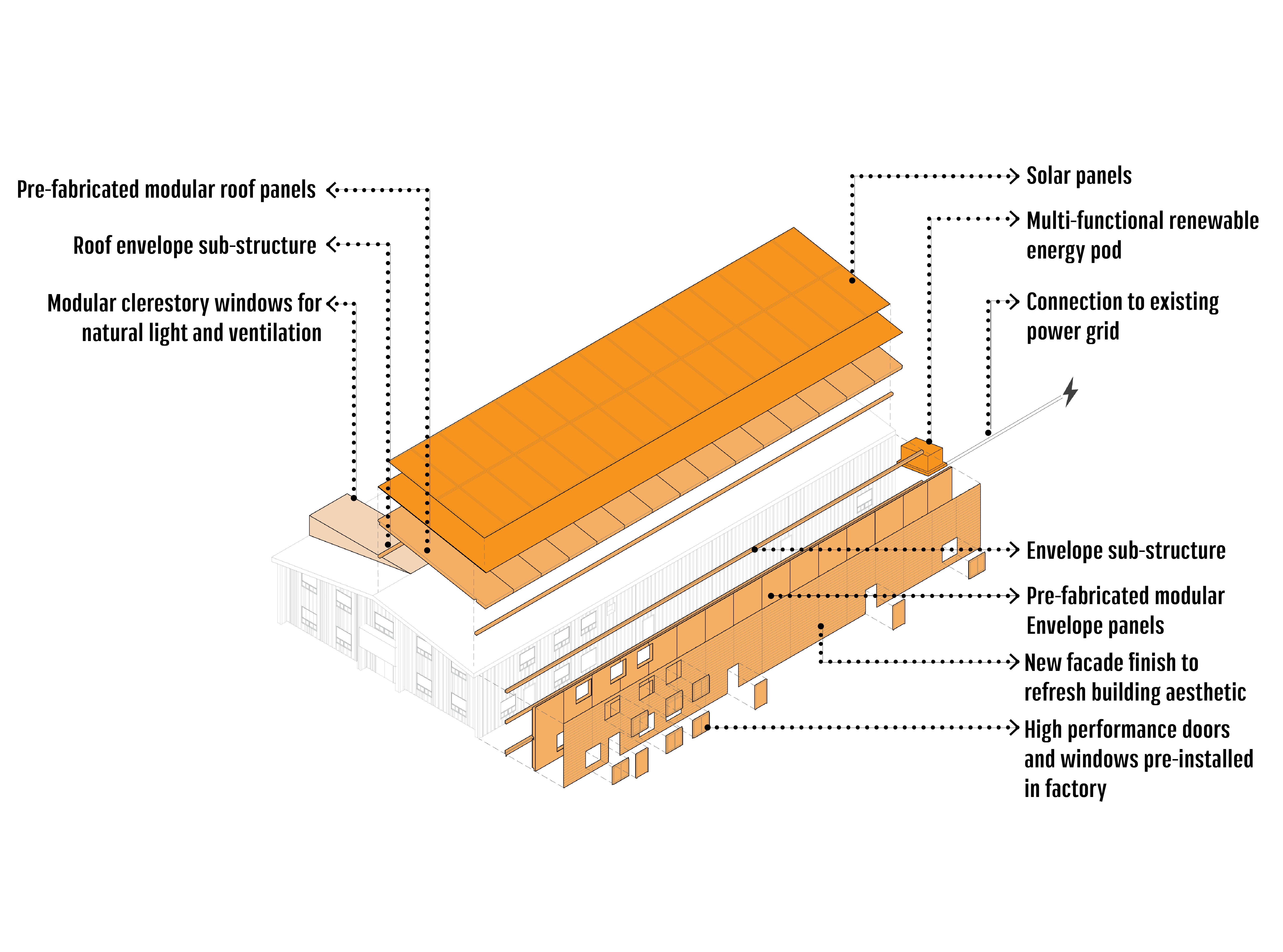

- Architectural solution and panel design

- Hygrothermal testing and modelling of panel designs

- Engagement with panel manufacturers

- Mechanical system design

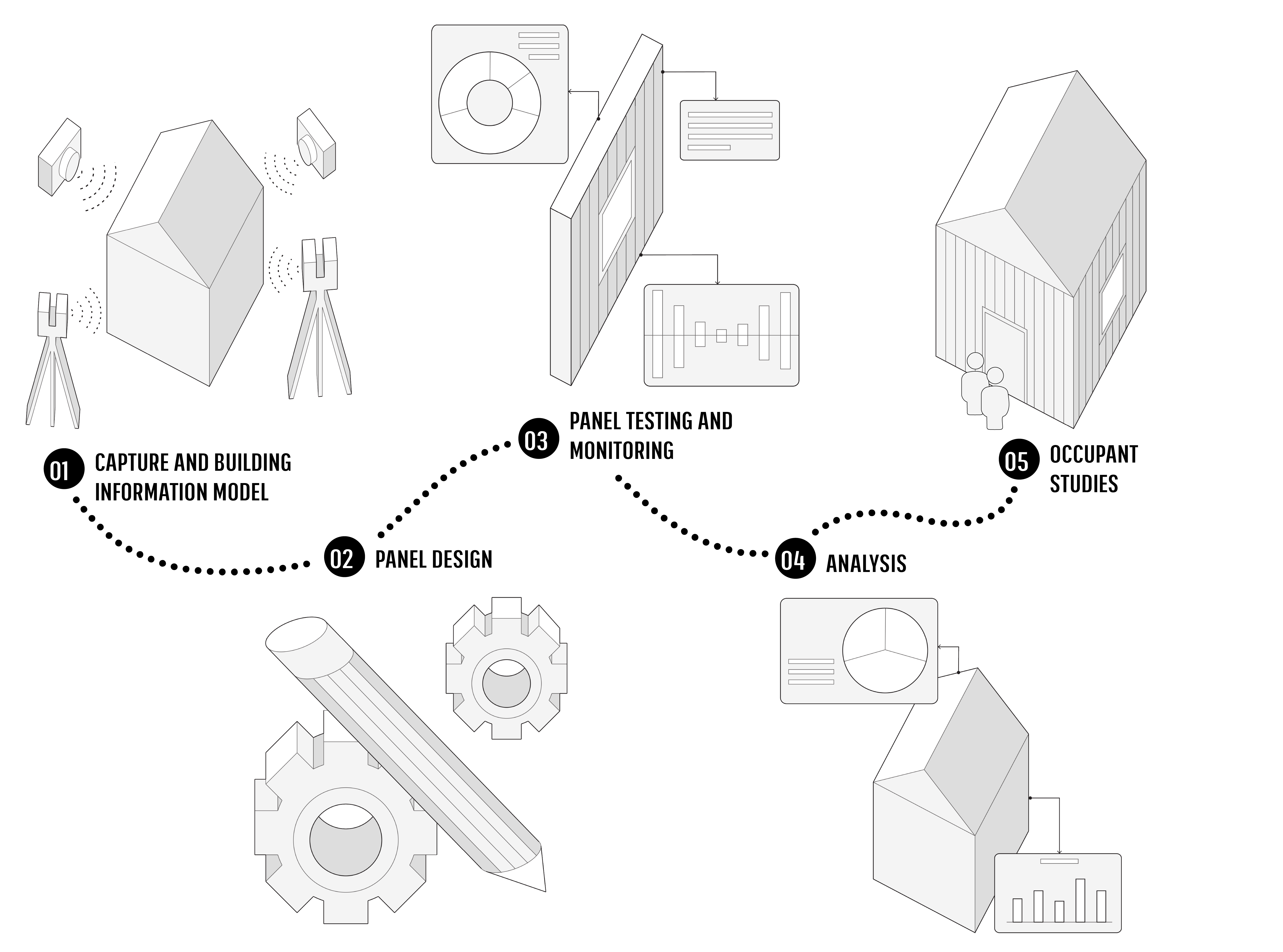

- Pre-/post-retrofit user studies

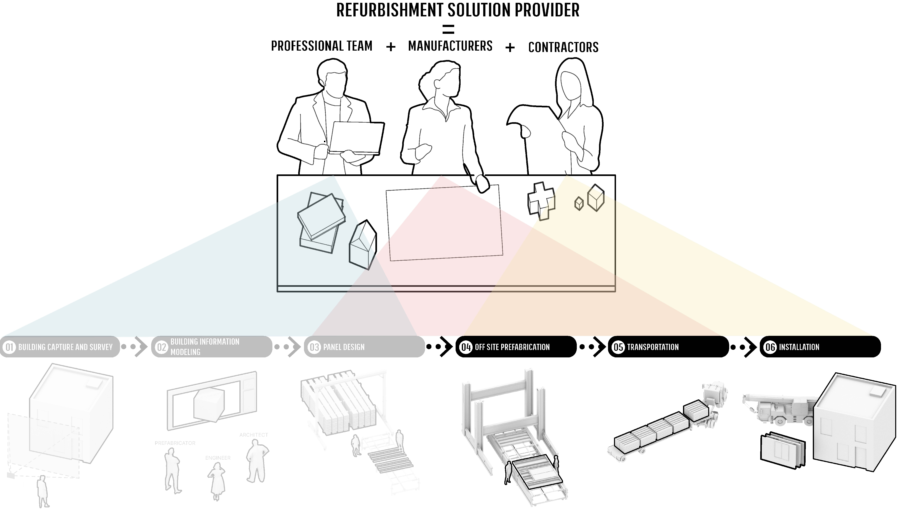

The project step by step

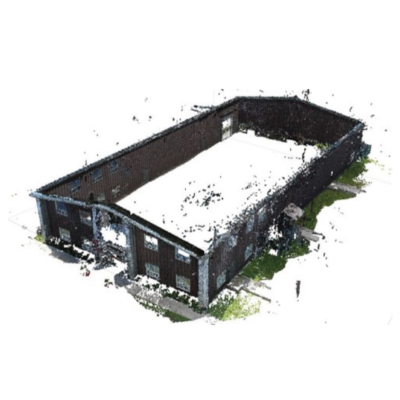

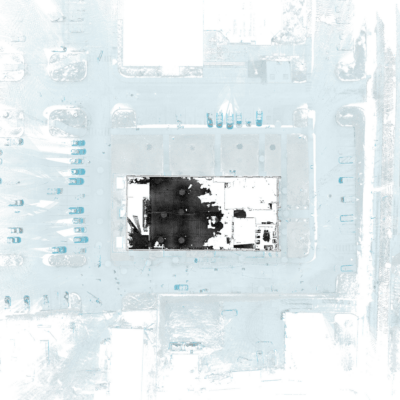

Building capture to building information model (BIM). A combination of surveying, laser scanning, and aerial based photogrammetry were used.

Building capture to building information model (BIM). A combination of surveying, laser scanning, and aerial based photogrammetry were used.

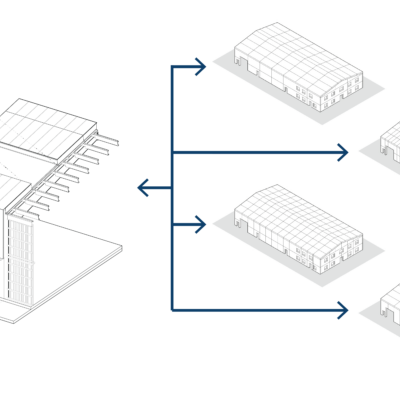

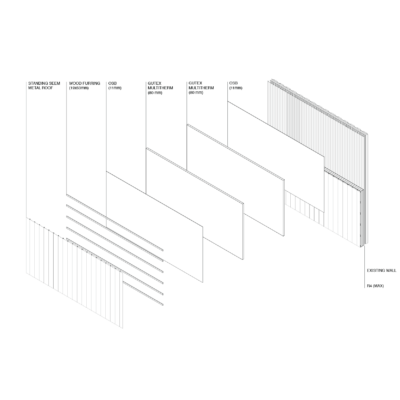

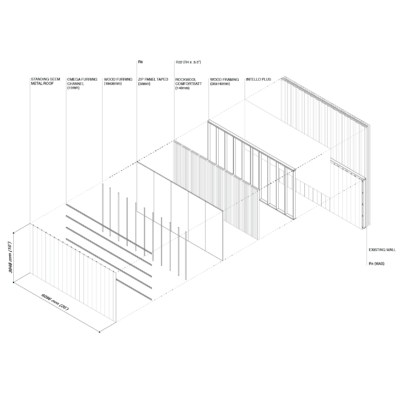

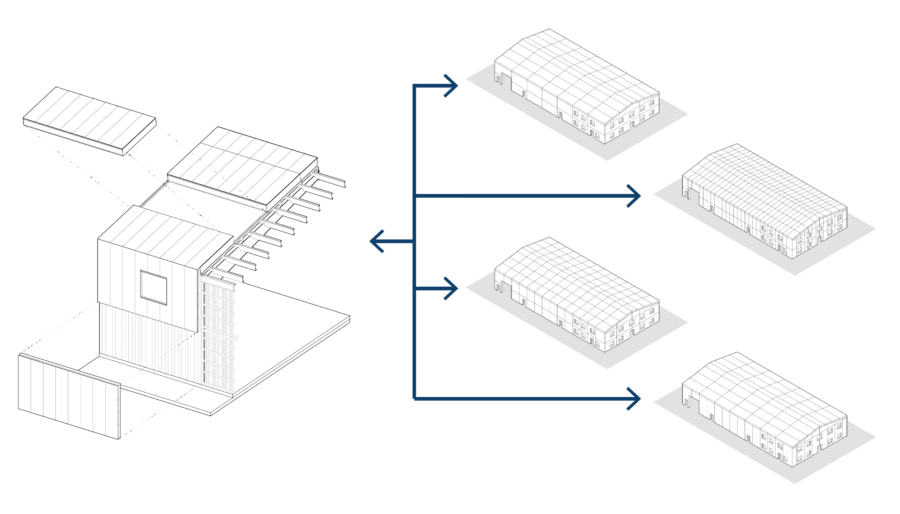

Development of panel solutions and panelization configurations. Each panel size and layout configuration has different advantages and disadvantages.

In situ testing of panel designs over a year at CABER. Data on hygrothermal performance and durability are used to assess risk, calibrate models and inform future designs.

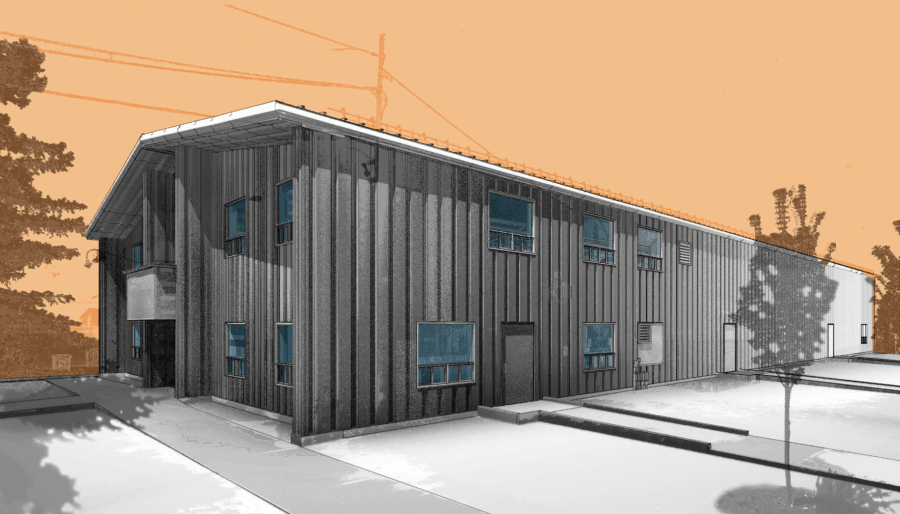

Design proposal with partial addition (Level 1 + Terrace).

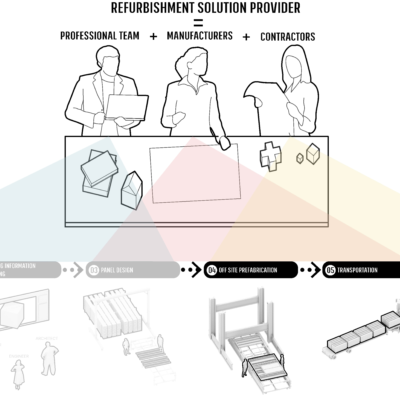

A professional design team, panel manufacturer and general contractor must work together to develop an optimal design that lends itself to large scale deployment.

Discover Our Collaborators

- Arrondissement de l’Île-Bizard—Sainte-Geneviève

- Société d’habitation du Québec

- Building decarbonization alliance

- Pembina institute

- Québec BVI – Bâtiment vert et intelligent

- ReCover Initiative

- Retrofit Canada

- The Atmospheric Fund (TAF)

- Transition Accelerator

- Zero Emissions Innovation Centre

- If Then Architecture Inc.

- Minotair Inc.

- RG Solutions